SORTİNG SERVİCE

Sorting services are offered at ZIRA PORT Marine Industrial Complex.

CRANAGE SERVİCE

Grab Bucket

The equipment shown in the image is likely a grab bucket, which is an accessory often used with cranes in cargo handling and construction operations. Grab buckets are primarily used for loading and unloading bulk materials such as sand, gravel, soil, coal, and similar substances. These devices consist of two jaws that open and close, allowing them to scoop up materials efficiently.

This type of equipment is commonly used in industrial ports like Zira Port for handling large volumes of bulk materials safely and quickly, playing an essential role in the cargo loading and unloading process.

Liebherr 924 excavator

The equipment shown in the image is a Liebherr 924 excavator. Excavators like this one are typically used in heavy construction and industrial operations for digging, lifting, and moving large quantities of material. This specific model, Liebherr 924, is known for its robust performance, versatility, and durability in handling various types of terrain and loads.

Key Features:

- Tracked undercarriage: Provides stability and maneuverability on rough terrain.

- Large bucket: Ideal for excavating soil, rocks, and other materials in large quantities.

- Hydraulic system: Allows for efficient and precise movements, making the machine highly versatile in construction, mining, and other heavy-duty tasks.

- Maximum lifting capacity: The HS 885 BHER is capable of safely lifting and moving heavy loads with great efficiency.

- Hydraulic system: Its powerful hydraulic system ensures precise and effective operation.

- Versatile applications: It’s used in large-scale projects like railway construction, bridge building, and energy projects.

- Multifunctionality: It can be modified with different attachments to handle various types of work.

Packing

Rebar Packing

Containers Stuffing

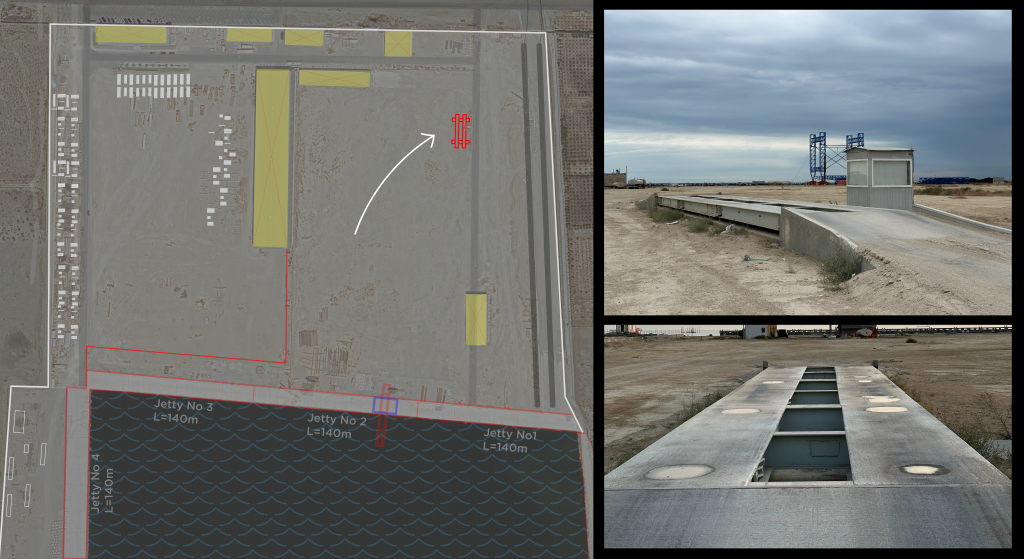

Scale

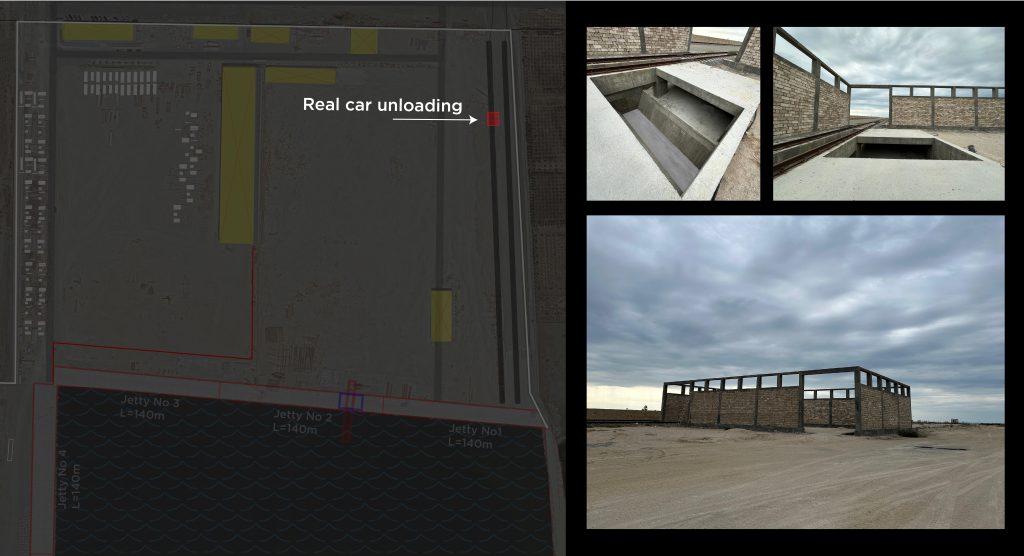

Rail car unloading

Rail car unloading is the process of removing cargo from railcars. It can be done using mechanical, pneumatic, or gravity systems, typically for dry goods, liquids, or powders. This process ensures efficient and safe handling of cargo at ports and industrial facilities.